Micro / Ultra Filtration

Micro / Ultra Filtration

NECESSITY/REQUIREMENT

- Micro filtration and Ultra filtration system are gaining popularity due to current scenario of shortage of fresh water availability. Ground water is depleting every day and it is becoming alarming situation for future.

- Treatment system based on reverse osmosis system produce waste of high salinity which creates discharge problem.

- Treatment system based on sea water reverse osmosis is expensive in operational cost.

SOLUTION

- Application of micro / ultrafiltration system can utilize treated effluent available from municipality or existing conventional sewage treatment plant.

- Water can be treated in terms of suspended solid, bacteria and viruses.

- Treated water can be utilize for secondary application such as ready mix, cement and block work, irrigation, cooling tower, flush in toilet system etc.

- Application of micro / ultrafiltration system can utilize treated effluent available from municipality or existing conventional sewage treatment plant.

- Water can be treated in terms of suspended solid, bacteria and viruses.

- Treated water can be utilized for secondary application such as ready mix, cement and block work, irrigation, cooling tower, flush in toilet system etc.

APPLICATION

- Micro filtration can treat water with high suspended solids (100PPM), high turbidity, bacteria contaminated water.

- Micro filtration can treat sea water as pretreatment system, surface water, river water, pond water and sewage treated water.

- Micro / ultrafiltration can treat the final water for bottling application.

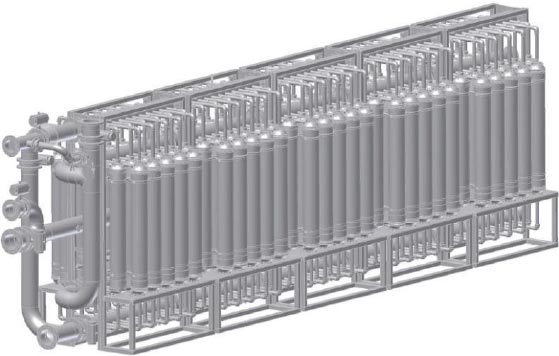

At our factory in Sharjah UAE, our team manufactures a full line of Microfiltration Systems designed for heavy or continuous duty service in many water applications where quality and dependable performance are key elements. Our standard.

Our engineers and water specialists are capable of manufacturing custom designed systems to fit our customer’s water application needs.

Specifications of Microfiltration/Ultrafiltration Plants

- Skid is MS-EP or Carbon Steel (CS) as per requirement.

- UF/MF Modules will be of Hydranautics or ASAHI Make for all series of Microfiltraion/Ultrafiltration plants.

- The system will be fully automatic by means of Pneumatic/Electrical Actuated Valves.

- The complete system will be operated with PLC panel with HMI.

- The headers & piping will be of uPVC/HDPE.

- Feed pump & CIP Pump for UF/MF plants will be from Grundfos/KSB depending on application.

- Pressure gauges in stainless steel 316 from WIKA.

- Instrumentation: Turbidity Analyzer, Online SDI Meter, Flow Transmitter, Differential Pressure Switch as per specifications

- Dosing pumps from Seko Italy or as per specifications.

- Control panel with SCADA system can be provided upon request.

Complete range of products or any specific requirements will be available on request, please send your enquiries to sales@celarwater.com